by Malcolm Woods

3D Printing

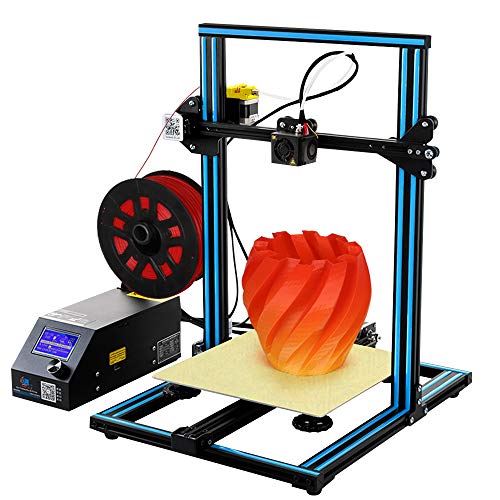

3D printing is a type of printing process where you can create three-dimensional objects just by a Digital file type. The device that performs this action is known as a 3D printer. But here the question is how do 3d printers work ?

It is also called additive manufacturing because, in the additive manufacturing process, the object is created with the additive process's help. In short, an additive process is in which we add successive layers of printing material until the object is created successfully. Each layer in the 3D object is a thin layer of sliced cross-sectional area.

The additive process is opposite to subtractive manufacturing, in which we cut down any object to create our desired object. Additive manufacturing is cost-effective than subtractive manufacturing.

To cut a long story short, 3D printers enable us to create complex objects with less material used and in a short time than traditional methods.

Raymond F. Jones first gave the imprecise concept of 3D modeling in the 1950s in his book named As "Tools of the Trade."

In 1971, Johannes F. Gottwald patented a paper about "Liquid Metal Recorded." After that, many scientists and researchers started working on 3D Modeling. Many models of 3D printers were tested afterward.

The first 3D printer was invented in 1981. Since then, many people have started working for its betterment. In the 20s, it is becoming the most oriented printing phenomenon, even at a small or organizational level. Within no time, let's have a look at the technologies and principles of 3D printing.

We start 3D printing with a three-dimensional model. After creating a 3D model in a digital file, i.e. Computer-Aided Design (CAD), it is downloaded as a library file. Further explanation is the following:

Numerous amounts of 3D software are available from the small level to the industrial level. Firstly, create a 3D model of the object that you want to make and download the digital file on your computer. Such files are downloaded in extension i.e. (.STL) or (.OBJ).

It is also known as a printable file. Now we have to print it from the printer by slicing the process.

Here in this process, a printable file is prepared for printing. Slicing is a process to convert our 3D model into layers. After a printable file, the object is converted into thousands of layers, and hence slicing is done.

After slicing, it is ready for printing. Then the slicing file is fed to the printer via USB, Wi-Fi, or any other source.

After modeling and slicing, now it's time to print the object physically. The principle of 3D printers is quite similar to the standard inkjet printers, where the nozzle of the inkjet printer moves back and forth to print something on the paper. Here in 3D printers, some wax, plastic, or other synthetic material is used instead of ink.

Briefly, it is just like thousands and millions of 2D printers are printing in layers horizontally to create a 3D object or model. The material used in 3D printers depends upon the characteristics of the object that we want to create. For your assistance, three-dimensional technologies and principles are discussed following.

There is a list of 3D printing technologies, but the following are three core and comprehensive technologies of 3D Printing:

Sometimes we need to create high-resolution items. In sintering technology, high-resolution objects are made by heating the plastic material below its melting point. It is further subdivided into two types: selective laser sintering in which thermoplastic powder is used. Another is metal laser sintering, in which metal powder is used for modeling.

As the name suggests, in this technology, the material is melted. Direct energy deposition, electron beam melting, and bed fusion are used to print objects by this technology. All the processes mentioned above use electron beams, electric arcs, and lasers, respectively.

It is also known as the oldest 3D printing technology. In this technology, to create parts of the objects, a photopolymerization process is adopted. This method uses a pure light source; light is focused on the metal object according to the calculated values to modify the metal's solid structure in thin layers.

There are several types of three-dimensional printing processes that depend on the applications, environment, availability of the printing material, and last and foremost is the final object.

3D printing is classified into seven groups by ISO (International Standard Organization) that are explained below:

In this type of printing, a layer of powdered material is placed layer by layer to create a 3D object. The powdered materials can be of metal, ceramic, or polymer sand. An example of binder jetting powered material is low melting metal Bronze. It is usually used in metal printing, ceramic modules, and color prototypes.

As light is a form of energy. In this type, a pure source of light is focused on creating an object. There can be other forms of energy like electron beam energy, arc energy, or laser energy. We use all these energies to mold the material into desired objects.

It is also known as (FDM). It usually uses a filament, which is fed by a nozzle to an extrusion head. By this process, the extrusion area is being heated, and it melts the material. After that, the melt material is deposited in the form of layers to form our required object.

The benefit is that it is a low-cost process. The advantage of this process is that the dimension accuracy is low.

It is similar to inkjet printing work but here, instead of placing the ink onto the pages, it fed the printing materials to different print heads. Needs mostly water-soluble materials. Material jetting is the most expensive method of three-dimensional printing. The benefit is that it is a very precise method of printing. It also has a disadvantage in that its parts start to brittle and degrade after some time.

It is a hybrid process. More than one form of energy (laser, electron beam, or light) is focused on some parts of the whole model. Similarly, all the details of the object are created by using different types of energies. In short, both melting and sintering processes are used in this type.

It is further divided into two processes, e.g., Ultrasonic Additive Manufacturing (UAM) and Laminated Object Manufacturing (LOM). UAM works by using different layers of adhesive materials, while UAM joins different types of laminated metal sheets by the welding process.

It uses light and selected liquid resigns to create three-dimensional objects. It is used where high accuracy of the dimensions is needed.

Following are world regions that are known for 3D printing hub:

Three-dimensional printing is one of the most top emerging digital technologies. 3D printers are economically best. The time saving is the most prominent feature while all the work is done digitally with the help of computer software.

Furthermore, the top three 3D printer companies are 3D systems Corp., Protolabs Inc., and FARO Technologies Inc.

Consequently, 3D printing looks like the future of the digital world due to numerous benefits.

|

|

|

|

About Malcolm Woods

Malcolm Woods is a blogger who enjoys writing about technology and solar power. He has a passion for learning new things, and loves to share his knowledge with others. Malcolm is also an advocate for sustainable living, and believes that everyone has a responsibility to do their part in preserving our planet.

|

|

|

|

Check These Out

Go for the FREE Gifts. Or check out for free energy books from our best collection.

Remove Ad block to reveal all the secrets. Once done, hit a button below

|

|

|

|